As well as being a driving instructor I also do a lot of work on my computer (websites, programming, and so on). So being comfortable is very important.

As well as being a driving instructor I also do a lot of work on my computer (websites, programming, and so on). So being comfortable is very important.

I’ve used all sorts of chairs over the years, and ones with arm rests or which tilt drive me nuts. I’d much rather sit up straight. So for some years now I have been using one of those ergonomic kneeling chairs, as shown in the photo above. I find them very comfortable and versatile, but the ones I purchased have all had serious quality issues. It’s not surprising when you consider that the most expensive ones can cost upwards of £1,000. Spending around £50, like I did, was bound to raise questions.

The first two I had were made of wood, In spite of getting them from different suppliers, it was obvious that they all come from the same place of manufacture. They were identical to each other, and they both had the same eventual problem. To start with, no matter how well you assemble them (they’re flat-packed), the screws work lose and they start to squeak. For a while, re-tightening works, but eventually the threads will not grip and the movement gets worse until there is an actual wobble. Eventually – and it doesn’t take that long – the wood splits due to the movement and the chair is unusable. Furthermore, even from first use, it is quite possible for one of the castors to fall off while you’re sitting on it or moving it.

In desperation, the third one I bought was more expensive and made of metal. I thought that a metal chair would be indestructible, but I was very wrong indeed. It was clear that the metal version came from the same original source as the wooden ones. Now, that shouldn’t have necessarily been a problem if the metal box sections used had been sturdy, but they weren’t. To keep costs down, the box section was made from a light gauge of steel, and although it was less flexible than wood, this rigidity meant that stress was concentrated across a very specific area near the seat. After about a year I could detect movement and when I checked, the metal had simply cracked.

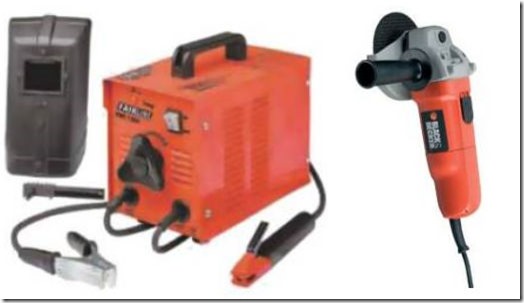

Anyway, like with most problems I encounter, I started to puzzle over how to get round it. I’d thought about drilling holes and fitting long bolts to act as supports – until I discovered how hard it is to drill holes in mild steel on something that is already assembled. The next thing that occurred to me was welding. I’d never done it before, and my only experience of it was my dad coming home with arc-eye on a regular basis when I was a kid (he was a welder, though admittedly on much bigger things), and I started thinking about hiring a welding machine. But then I found out how small and cheap they are. I picked one up for £50 from Makro. At the same time I also bought an angle grinder for £20 (more on that in a later article).

I got a couple of lengths of mild steel flat bar from B&Q and set about welding some strengthening spars to my rickety chair. This was quite successful and the repair, albeit temporary, was good.

By this time, I had discovered that welding isn’t easy. Not at first, anyway. Striking an arc is pretty simple, but keeping it is a skill. Welding rods get used up very quickly, and it is easy to get one stuck. Welded metal gets very hot, the heat spreads quite a long way through a metal object. Paint is flammable, even when it’s nowhere near the actual weld.

As a result of this article, I’ve had a few hits from people using the search term ‘welding rod keeps sticking’ or some such. This can happen if you are holding the rod too close to the weld – the current is therefore lower, so I guess the weld is cooler and solidifies more quickly, hence the stuck rod. It is even worse if you’re so close that the rod keeps touching the weld, as this can cause the arc to extinguish – also resulting in a frozen rod. Also make sure you are using the right current setting for the thickness of rod you’re using.

But back to the story. The idea of building an ergonomic kneeling chair from scratch had been running around in my head for some time, and now that I knew how to weld, the idea started jumping up and down as well. I found a company called Metals4u on the Internet, and they will supply any quantity of metal you want, and their prices are very good. So the project was set to get going.

The project summary can be found here.

* Note that Metals4U asked me to remove the direct link to their site. As far as I understand it, as well as getting too big for its boots these days, Google also appears to have outgrown its brain and is penalising companies for links to their websites from “lesser ranked” websites such as mine. Their web address is metals4u dot co dot uk.