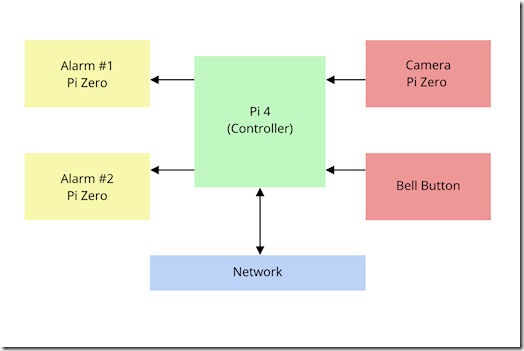

Update: I’ve changed my plans on this and will not be trying to construct a complete Ring-type doorbell after all. My experiments with CCTV cameras have shown I can build a suitable system without having to mess with the motion detection. I can let the camera do that.

Overview

I’ve been having problems with my birdbox camera. I’ve been having problems with my Ring doorbell. I’ve also been playing around with various CCTV cameras.

I’ll get on to the birdbox issue in a moment, since it is the primary subject of this article. But for general background:

- my Ring Doorbell issue is to do with the fact that Ring is discontinuing the desktop app, which I can access instantly from my PC when I receive a proximity alert or a doorbell push to see who is there. Ring’s intended alternative is a web-based approach, which is slow, and which also requires you to log in via 2FA if you’re inactive for more than a few minutes – and by the time you have, whoever there is gone. So I formulated the idea of building my own video doorbell.

- my CCTV interest developed from the Ring issue, and from learning a heck of a lot about IP camera networking from my birdbox camera, which gave me ideas for a home CCTV system.

Let’s not worry about how these all fit together in the history timeline of my mind, because I’m not sure myself! Right now, my birdbox camera is my main focus.

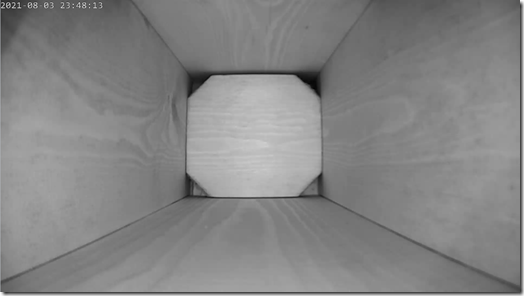

I installed a birdbox last year, fitted with a Wi-Fi HD camera. After some messing around to get a decent Wi-Fi signal to the end of the garden it worked brilliantly, and I got a night time resident roosting Great Tit within days of me putting it up. I had high hopes of a nesting situation come the Spring. Whenever the bird came in (and I will now refer to it as ‘she’, which will make sense shortly), she would often jump up behind the camera to pick off insects. That was no problem until the one time she did it and the signal disappeared, because she’d pulled the Wi-Fi antenna off the top of the camera.

I didn’t want to risk another Wi-Fi camera – my relationship with Wi-Fi is quite rocky at the best of times, and having a small bird disable it just added to that – so I decided to fit a wired one. After I’d put it in and run the network cables and PoE switches to the house, I had the video feed back. And as I’d noticed a lot of small twigs underneath the birdbox by the time I did that, I discovered she’d built a nest (when roosting over winter, she just settled on to the wooden floor). I was able to see the camera feed on my home network, and also able to stream the RTSP feed to the blog (and anyone else) so they could watch it live. It worked for about a week, and then the RTSP feed was lost – possibly a result of updating the camera firmware, or maybe because of a camera fault. I’m still pushing that side of things with the supplier, but at least I still have live access on my home network, as she has now laid eight eggs and is incubating them.

The problems with the camera set me off on my usual thought process, which amounts to this: well, OK. I can buy another one of those. But what if I made one myself?

In the case of a camera, and if it were based on something I had programmed myself, I would have full control over operation and repair. But what about the size of it? Those off-the-shelf birdbox cameras measure about 40mm x 40mm x 23mm, so there’s no benefit in building one the size of a refrigerator. But the Raspberry Pi Zero (a full computer) measures about 65mm x 35mm x 2mm, and a HD camera for it is even smaller, though it adds maybe another 5mm to the overall thickness. And I’ll cover this later, but a suitable add-on which gives PoE and wired networking capability adds a further 30mm to the thickness, so hardware-wise you could have a camera system which is only 65mm x 35mm x 40mm, and in a case perhaps 75mm x 80mm x 57mm (I already have one identified). That would fit in the birdbox easily and also give internal room for cables. The only issue from then on would be software.

The beauty of the Raspberry Pi is that people out there have already done brilliant things, and the software they produce is usually available for free. And software for creating ONVIF camera applications does exist.

However, many of those solutions have too wide a scope. In my case, I just want a raw ONVIF camera with no frills (other than a microphone, which might be problematic on a Pi), so I can get the fastest and highest quality image, then monitor it using Surveillance Station on my NAS. I can fiddle with motion detection – if I actually need it in my birdbox – within Surveillance Station. My approach is to keep things simple, and then build on that if I want bells and whistles later. But the DIY projects online try to put all the bells and whistles in right at the start, and many are likely to be superfluous to most people. Motion detection within the camera, which is one such popular feature, ramps up the processing overhead immediately.

This project will be similar to the Kneeling Chair one I did some years ago. I will add instalments as I go along. But right now I have several of these – the Pi Zero, cost £13.50:

Various images removed as the plan has now changed:

One of these – the PoE HAT, cost £22:

I have this on notify for when it becomes available – it’s an autofocus HD camera for the Pi (though the actual one I end up using might change), cost £23:

And this is the case I am likely to use, which all of the above will easily fit into – cost £25:

Obviously, I will need a few more bits and pieces – some of which I already have – and I haven’t mentioned IR Cut for night vision at this stage. However, I will detail those as I go along. And the worst part is always getting the finished product – building an ONVIF device will be relatively easy, but mounting it compactly in the case so it can be used in a practical setting will be the hardest task of all, since I will have to drill that case and then make sure it is still at least water resistant when I mount it Inside the birdbox. It won’t get wet in there, but it will be subjected to variations in temperature and humidity.

Update: Hold on. I just had another idea for the birdbox camera issue. I have discovered that even though a typical CCTV camera looks like a Danish salami, most of the inside is empty space and the camera assembly is a section at the front.

I just tested one I have strapped to my second birdbox and it works. So if I disassemble it and re-package it into a suitable case, I will have a ready-to-use birdbox camera with all the bells and whistles of a CCTV camera.

I have a new toy. A birdbox with a camera fitted into it. I will be installing it outside over the next few weeks, and maybe I’ll get some roosting birds in the autumn and winter, but I’m hoping to get them nesting next year.

I have a new toy. A birdbox with a camera fitted into it. I will be installing it outside over the next few weeks, and maybe I’ll get some roosting birds in the autumn and winter, but I’m hoping to get them nesting next year. As people will no doubt have found out, those members of our society who don’t wash their hands even after they’ve had a shit have been resolutely buying crates of hand sanitizer and thus preventing those of us for whom it might have some benefit getting any of it. In some cases, they’re selling it on eBay for stupid prices.

As people will no doubt have found out, those members of our society who don’t wash their hands even after they’ve had a shit have been resolutely buying crates of hand sanitizer and thus preventing those of us for whom it might have some benefit getting any of it. In some cases, they’re selling it on eBay for stupid prices. As well as being a driving instructor I also do a lot of work on my computer (websites, programming, and so on). So being comfortable is very important.

As well as being a driving instructor I also do a lot of work on my computer (websites, programming, and so on). So being comfortable is very important.

As I mentioned in the previous post, it was -9ºC again this morning. It never got higher than -2ºC all day (so much for the forecast high of 1ºC) and that was with full sunshine throughout.

As I mentioned in the previous post, it was -9ºC again this morning. It never got higher than -2ºC all day (so much for the forecast high of 1ºC) and that was with full sunshine throughout.